Structure buildings and fire – facts

The fire problem continues to account for the vast majority of civilian casualties in both residential and non-residential fires around the globe.

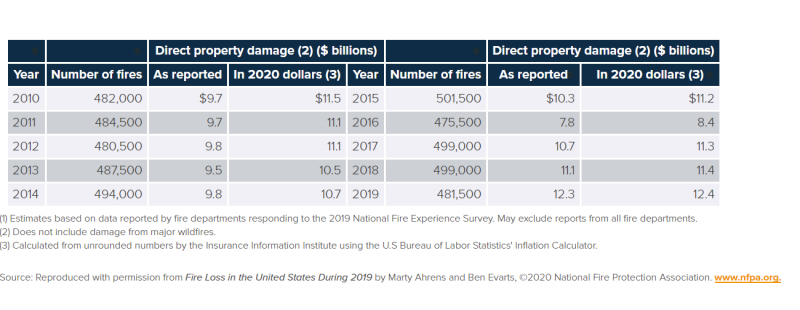

According to the statistics, it is estimated that, in Europe, around 5000 people lose their life due to building fires. Additionally, the National Fire Protection Association (NFPA) of United States responded to an estimated average of 481,500 home structure fires in 2019. These fires caused an annual average of 3,704 civilian deaths; 16,600 civilian fire injuries; and $12.4 billion in direct property damage.

Fire safety should be a top priority when planning any type of construction. Greater emphasis on the structure and fire-resistant certified materials is important for both the roof and the walls to achieve the maximum level of protection against fires, especially in new buildings.

In case of a large fire the structural safety of the building needs to be ensured so that it doesn’t collapse on occupants or firefighters. When structural fire protection is designed and applied properly, the building’s structural integrity would be maintained when exposed to fire.

Passive fire protection

While most people are familiar with the basics of an active fire suppression system, including the use of sprinklers, fire extinguishers etc., passive fire protection is what usually contains a fire at its first point of origin.

Passive fire protection is usually structural and integrated into the building envelope. A fire strategy will only achieve maximum effectiveness if the passive fire protection measures like non-combustible or fire-retardant membranes, insulated fire-resisting partitions, cavity barriers, specialist fire-stopping of gaps in structure with their proven fire performance properties, are built into the fabric of a building.

These systems require no action should a fire break out – they are part of the construction of the building. The fire can more likely be contained and not quickly spread to the rest of the building. It plays a vital, and increasingly significant role in safeguarding people, as well as limiting damage to buildings and their contents from fire and smoke.

Consistent use of integrated active and passive fire protection is the most effective way to minimize this risk and protect people’s lives, their property and the environment.

Holistic framework at the core of structural fire safety

Risk and Performance

The literature study indicates that fire safety is still considered relatively late in the design process and does not always carry through to the operational phase of a building. Inclusion of fire safety in the early stages of system development, in building planning and design, would help to alleviate many fire safety issues before they truly emerge, e.g. questions of material fire performance, system design, and first responder accessibility.

Societal Objectives

It is argued that there is a need to broaden our basic understanding of societal objectives as being many and not one, which must work together, and to include resilience into the context of ‘Sustainable and Fire Resilient’ (SAFR) buildings and communities.

Green Building Materials

‘Green’ building materials, systems and features are collectively referred to as the “Attributes” of a building. These attributes are designed to meet societal objectives and, need to be considered in terms of risk and performance. Fire incidents indicate that sometimes the adoption of such systems can have unexpected consequences when safety considerations are not considered early in the development phase or where unexpected combinations of materials are used to create and install systems outside of the original specifications.

Three key trends connected specifically with ‘green’ attributes are:

1. The need for renovation of an aging building stock

2. The presence of new technologies continuously being introduced.

3. The increased desire to develop a circular economy.

Control Mechanisms

Control Mechanisms represent a fundamental part of a holistic framework. Building regulations and standards, together with component testing and inspection play a key role in ensuring that established levels of safety are maintained over time.

Sustainable fire-rated membranes

As part of the passive protection, sustainable fire-rated membranes are critical components in any type of assemblies, providing stability and integrity to a building or structure in case of fire. If the internal section catches fire, it does not let it spread and protects the rest of the building and adjacent properties. However, a fire can have both an internal and external cause. Not only should a building provide a reasonable degree of fire resistance internally, but it should also prevent an external fire from spreading to another building.

External fire-rated membranes protect a structure from fire and natural hazards associated with the local environment, including rain, hail, high winds and temperature extremes.

The other attribute that needs to be considered is, for resisting a fire, especially in public and high-rise construction, air and windtight membranes and all other structural materials must be fire-retardant, non-combustible, or limited combustible. Non-combustibility is the most stringent standard for fire performance of materials, they can be used without restriction in any part of building construction and finishing. Their use ensures that hazards due to smoke and toxic gases are minimised and that the fabric of a building makes no contribution to fire.

When evaluating a structure's fire performance, contractors must be able to balance combustibility against a variety of performance variables. While it may be appealing to make the whole structure incombustible, it is not recommended by the experts as this may have an effect on the building's hygrothermal efficiency or on-air leakage.

The aim is to strike a balance between the fire-related aspects of the design and other factors such as airtightness, energy efficiency and healthy indoor environments, while not endangering significant fire safety design concerns. Some of the most technologically innovative building membranes on the market are assisting in achieving these standards.

Incombustible materials should be used where absolutely appropriate and practical, but where easily ignitable materials must be implemented, the fire risk should be well recognized and minimized.

The only way to control the fire from engulfing to larger areas of the building from the inside is to ensure that the walls, ceilings, and floors can withstand being exposed to a fully developed fire on one side while not transporting heat, flames or toxic gases to the other side.

If the facade and internal wall system, including cladding, airtightness and/or insulation, consists of non-combustible materials, however, the flames might eventually reach and breach the assembly, but the process will be comparatively slow as the building envelope wouldn’t contribute to the spread of the fire (and resulting smoke).

With the rapid development of economy and society and the acceleration of urbanization around the world, there are more and more commercial and residential construction with growing volume and larger height. As a result, building codes for high rises emphasize a sustainable, robust design planning in terms of fire safety. The fundamental regulation in fire safety for high-rise and high-risk buildings is that the construction must remain intact throughout the fire and offer protection for the occupants until they can be evacuated. There must be no structural failure should there be a burnout in any portion of the building. Fire retardant, non-combustible membranes can be used internally and externally as protective sheathing. Sustainable fire-rated membranes are not only a requirement of the building regulations, but the way to save property and human lives in the event of a fire.

UK and EU building regulations

The Building Regulations governing fire safety are designed to preserve life, and this must always be the primary consideration in the design and construction of any building. To take care of such provisions all countries have their own standards for fire-resistance of buildings based on fire tests. As a function of a building element, standards employ three major fire safety criteria. These include stability (the ability to withstand applied loads during fire exposure), integrity (the ability to prevent fire propagation due to cracks and fissures), and insulation (the ability to insulate the unexposed faces during fire exposure).

The building regulations consider the following passive aspects of fire safety in the construction of buildings.

• Requirement- Control of Internally fire spread (linings): The wall lining i.e. plaster, plasterboard or wooden boards on the walls and ceiling will resist the spread of flames and give off only reasonable levels of heat, if on fire.

• Requirement- Control of Internal fire spread (structure) will be maintained during a fire, and fire spread will be prevented.

• Fire and smoke will be prevented from spreading to concealed spaces in a building's structure by Fire Stopping and Fire Cavity Barriers.

• Requirement External fire spread – The external walls and roof will resist spread of fire to walls and roofs of other buildings. However, not all buildings are required to have non-combustible exterior finishes.

In England, building regulations covering fire safety issues within and around buildings are specified in Approved Document B (Fire Safety) Volume 1 (dwelling houses) and Volume 2 (buildings other than dwelling houses). These building regulations consider five aspects of fire safety in the construction of buildings:

For all materials used in the building, documentation sets the minimum specifications (BS 476 and EN ISO 13501-1), including detailed installation criteria. Sections 4, 6, 7, and 11 of the BS476, the most frequently used in the UK, examine combustibility and fire spread characteristics.

Materials in Class A1 and Class A2 are completely non-combustible when exposed to fire, Class B products are combustible but contribute "a little" to overall fire production, whereas C-E products contribute significant amounts to overall fire development. Class F for materials that fail Euroclass E criteria.

Smoke causes over 60% of deaths in fire across the EU. Additional classifications are used to signify smoke production (s1, s2, and s3), with s1 denoting extremely minimal smoke, s2 indicating limited smoke, and S3 representing no smoke demands. Some construction products, like those made of polystyrene, can melt and ignite to form Flaming Droplets. The classification system also ranks the level of release of Flaming Droplets /particles as d0 [none], d1 [some], and d2 [quite a lot].

In order to assess the appropriate classification, a product must be tested in accordance with EN 13823 (known as a ‘single burning item’ test): “Reaction to fire tests for building products- Building products excluding flooring exposed to the thermal attack by a single burning item.” and EN 11925-2 (Single Flame Source Test):” Reaction to fire tests for building products – Part 2: Ignitability when subjected to direct impingement of flame”.

Emphasizing the importance of standards and codes in reducing the burden of fire, a detailed standards and codes strategy is presented by the countries. European version of the standards and code strategy includes fire-protective membrane requirements to mitigate the consequences of fires that do occur. The regulations demand that the fire-rated membranes perform as A1 or A2,s1-d0, for buildings higher than 11 m and ‘accommodation buildings’. This includes commercial buildings, schools, hospitals, nursing or retirement homes with a large number of visitors or occupants, and where rapid spread would be most likely to prevent occupants from escaping.

To ensure that the client's goals are met, the design of fire protection services requires a thorough understanding of the respective country's Building Code.

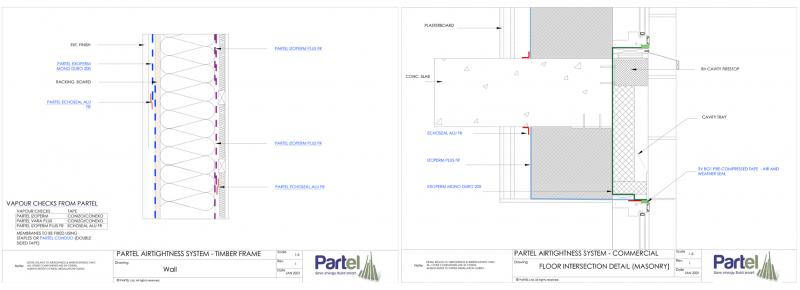

Partel’s Technical Solutions

Partel's technical fire-rated membranes are key components in fire-resistant buildings, for both the internal and external envelope. The high-performance solutions are designed to provide airtightness, energy efficiency and moisture management, improving indoor air quality and providing exceptional fire safety to the building and its occupants.

IZOPERM PLUS FR is an advanced non-combustible vapour control membrane Euroclass A2-s1-d0 that is air and vapour tight, increasing energy efficiency and lowering the risk of condensation inside residential and commercial buildings. It is capable of meeting the performance requirements of the interior-originating fire exposure conditions, which is where most of the damage is usually done.

It acts as a Passive Fire Protection; non-combustibility is a core feature of IZOPERM PLUS FR and it protects the essential structural components and slows down or confines the fire once it’s created

The IZOPERM PLUS FR membrane has been tested and has successfully received the Class A2-s1-d0 standard in accordance with EN 13501-1.

EXOPERM MONO DURO 200 is premium class of protective flame-retardant membrane - Euroclass B-s1, d0, designed for the external wall and roof. Its special two-layer formulation combines a TPU coating with a technical PES non-woven fabric to create a membrane that is water and wind resistant, has outstanding ageing resistance, and provides increased fire-resistance within the building fabric.

Both membranes would allow our customers to enhance building safety, expand design options, and increase resilience, making it easier to create more reliable, energy-efficient, and sustainable fire-resistant structures.

To learn more about IZOPERM™ PLUS FR and EXOPERM™ MONO DURO 200 fire-rated solutions, view Product Page. Full technical and sales support are available at Partel to provide information and assistance to help in the design and installation of IZOPERM™ PLUS FR and EXOPERM™ MONO DURO 200 product systems.

References

- https://www.nfpa.org/-/media/Files/News-and-Research/Fire-statistics-and-reports/Building-and-life-safety/oshomes.pdf

- https://www.modernbuildingalliance.eu/EU-fire-safety-guide

- http://highperformanceinsulation.eu/wp-content/uploads/2020/10/PU-Europe-Fire-Safety-Handbook-_-European-fire-standards-and-national-legislation-_June-2020.pdf

- https://www.gov.ie/en/publication/303fa-current-edition-technical-guidance-document-b-fire-safety-volume-2-dwelling-houses-supplementary-documents-supplementary-guidance-to-technical-guidance-document-b-fire-safety-volume-2-dwelling-houses-2017/

- https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/937931/ADB_Vol1_Dwellings_2019_edition_inc_2020_amendments.pdf

- https://cfpa-e.eu/the-eu-fire-safety-guide/

- https://www.nfpa.org/News-and-Research/Publications-and-media/NFPA-Journal/2020/September-October-2020/Features/Fire-Loss